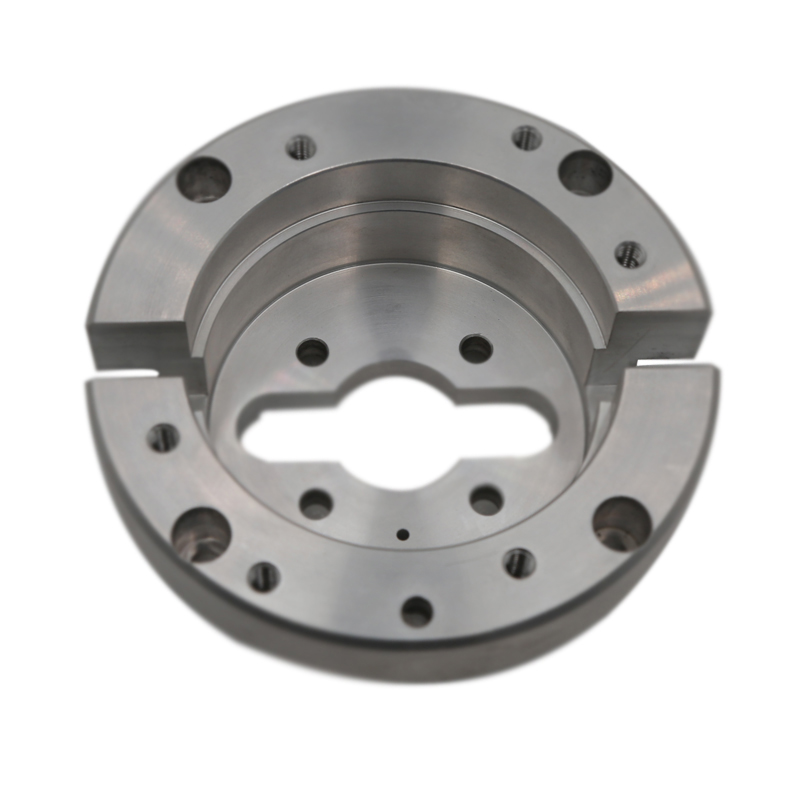

Alloy Steel CNC qaybaha machining

Qalabka la heli karo

birta daawaha 1.7131 |16MnCr5: Alloy steel 1.7131 waxaa sidoo kale loo yaqaan 16MnCr5 ama 16MnCr5 (1.7131) waa darajada birta daawaynta hoose ee injineernimada oo caadi ahaan loo isticmaalo codsiyo kala duwan.Waxaa caadi ahaan loo isticmaalaa gears, shafts, gearboxes, iyo qaybaha kale ee farsamadataas oo u baahan adag tahay oogada sare oo ay xidhato iska caabin.

birta daawaha ah 4140| 1.2331 |EN19| 42CrMo: AISI 4140 waa bir daawaha hoose oo leh chromium iyo molybdenum ka kooban oo hubinaya xoog macquul ah.Waxaa intaa dheer waxay leedahay iska caabin wanaagsan oo daxalka atmospheric.Waxaa si weyn loogu isticmaalaa warshado badan sababtoo ah sifooyinka wanaagsan.

birta daawaha 1.7225 |42CrMo4:

Faa'iidada birta Alloy

birta daawaha 4340 |1.6511 |36CrNiMo4 |EN24: Caan ka ah adaygeeda iyo xooggeeda 4140 waa bir daawaha hoose ee kaarboon dhexdhexaad ah.Waxa lagu daweyn karaa kulaylka si heerar sare ah iyadoo la ilaalinayo adkaanta wanaagsan, xidho iska caabbinta iyo heerarka xoogga daalka, oo ay weheliso caabbinta daxalka ee jawiga wanaagsan, iyo xoogga.

birta daawaha 1215 |EN1A:1215 waa bir kaarboon ah oo macneheedu yahay kaarboonka sida curiye alloying ugu weyn.Waxaa badanaa la barbar dhigaa birta kaarboon 1018 sababtoo ah isku midka ah codsiyadooda, laakiin waxay leeyihiin kala duwanaansho badan.1215 birta waxay leedahay mashiin ka fiican waxayna xajin kartaa dulqaad adag iyo sidoo kale dhamaystir dhalaalaya.

Waa maxay nooca daaweynta dusha ku habboon qaybaha mashiinnada CNC ee alaabta birta Alloy

Daaweynta dusha ugu caansan ee qaybaha mashiinnada CNC ee walxaha birta daawaha ah waa oksaydhka madow.Tani waa hab deegaanka u wanaagsan taas oo keenta dhamaystir madow oo ah daxal iyo xidhashada adkaysi u leh.Daawaynta kale waxaa ka mid ah gariir-deburinta, toogashada toogashada, baqashada, rinjiyeynta, dahaarka budada, iyo koronto-samaynta.