Awoodaha adeegga ee CNC-da

From prototyping to full production runs. Our wide range of CNC lathes and turning centers will allow you to produce highly accurate, high quality parts to meet even your most complex requirements. Can’t decide which machining process is best for you? Just send us drawing by email:rfq@lairun.com.cn

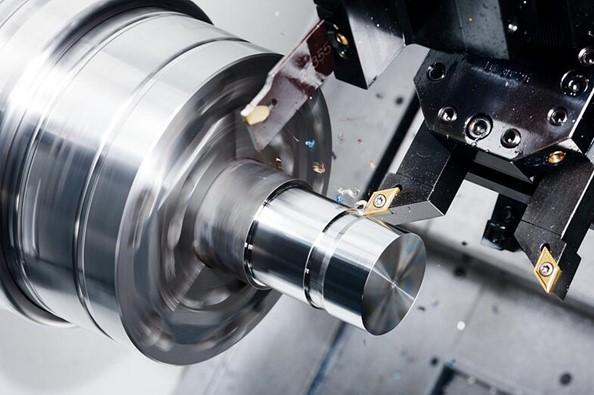

Qalabka CNC

Mashiinnada rogrogmada CNC waxay awoodaan inay bixiyaan qaybo qiimo jaban oo loogu talagalay joomatariyada cylindrical fudud. Nidaamkeena rogrogmida CNC waxay soo saartaa tusaalayaal caado ah iyo qaybaha wax soo saarka dhamaadka isticmaalka sida ugu dhakhsaha badan 1 maalin. Waxaan isticmaalnaa lathe CNC oo leh qalab toos ah si astaamihiisa sida axial iyo radial godadka, dabaqyada, jeexjeexyada, iyo boosaska lagu farsamayn karo.

Jeedinta CNC waxaa badanaa loo isticmaalaa:

Qaababka shaqada iyo qaybaha isticmaalka dhamaadka

Qaybo leh astaamo cylindrical ah

Qaybo leh godadka axial iyo radial, dabaqyo, jeexdin, iyo godad

Qaybo leh biraha, Valves, Lock ringings iyo cylinders.

Waxaan bixinaa jawaab celin degdeg ah si aan u hubinno in qaybtaada loo hagaajiyay habka rogista CNC oo ay ku habboonaato shuruudaha aad u baahan tahay. Soo saarahayadu waxay keeni karaan qaybo tayo sare leh oo bir ah iyo caag CNC ah oo loogu talagalay soo saarista degdega ah. wer iyo awoodaha xawaaraha ee saameeya noocyada qaybaha lagu samayn karo dhaqaale ahaan.

Waa maxay CNC Turning? Siday u shaqeyso?

●Kombuyuutarta Koontaroolka (CNC) leexashada waa hab wax soo saar oo adeegsada lathe si ay u abuurto qaybo sax ah oo ka samaysan walxo kala duwan, sida birta, balaastikada, iyo aluminiumka. Mashiinka lathe wuxuu ku wareegaa qaybta shaqada halka qalabka goynta uu u qaabeynayo cabbirka iyo qaabka la doonayo.

●Nidaamka rogidashada CNC waxay ku bilaabataa naqshad la sameeyay iyadoo la isticmaalayo software-ka-caawinta Kombiyuutarka (CAD). Naqshadeynta ayaa markaa loo rogaa kood kood uu akhrin karo oo la socon karo CNC. Hawlwadeenku waxa uu dejinayaa mishiinka isaga oo ku dhejinaya qalabka shaqada ee laashka oo ku rakibaya qalabka lagama maarmaanka ah.

●Marka mishiinku diyaar yahay, barnaamijka CNC waa la raray, hawlwadeenna wuxuu bilaabayaa habka. Lathe CNC wuxuu ku wareegayaa qalabka shaqada xawaare sare halka qalabka goynta uu ku socdo walxaha, isaga oo ka saaraya walxaha xad-dhaafka ah ilaa qaybtu gaadho qaabka iyo cabbirka la doonayo.

● leexashada CNC waxay ku siinaysaa faa'iidooyin badan marka loo eego hab-rogid dhaqameedka. Marka hore, saxnaanta iyo saxnaanta leexinta CNC ayaa aad uga sareysa leexashada gacanta. Sababtoo ah mashiinka CNC waxaa loo qorsheeyay inuu si sax ah u raaco naqshadeynta, halka leexashada gacanta ay ku tiirsan tahay xirfadlaha iyo khibradda hawlwadeenka.

●Waxaa dheer, leexashada CNC aad ayey uga dhaqso badan tahay gacan-rogista. Lathe CNC, hawlwadeenku wuxuu dejin karaa oo maamuli karaa qaybo badan isku mar, taasoo keentay heer wax soo saar aad u sarreeya. Jeedinta CNC sidoo kale aad bay uga waxtar badan tahay, oo leh qashinka shay yar iyo kharashyada shaqada oo hooseeya.

●Dukaankayaga mashiinka CNC, waxaan bixinaa adeegyo rogid degdeg ah oo CNC ah oo tayo sare leh. Qalabkayaga casriga ah iyo hawl-wadeennada khibradda leh ayaa noo oggolaanaya inaan abuurno qaybo gaar ah oo leh saxnaan iyo xawaare gaar ah. Waxaan ku takhasusnay wax-soo-saarka, waxaanan xamili karnaa socodsiinta wax-soo-saarka yaryar iyo kuwa waaweynba.

● Gebogebadii, rogid CNC waa hab wax soo saar aad u hufan oo sax ah kaas oo soo saari kara qaybo gaar ah si dhakhso ah oo sax ah oo gaar ah. Haddii aad u baahan tahay hal tusaale ama socodsiin wax soo saar oo weyn, leexashada CNC waa doorasho aad u fiican baahiyahaaga wax soo saarka.

Noocyada CNC Lathes

Waxaa jira noocyo badan oo lathes ah, laakiin kuwa ugu caansan waa 2-dhidib CNC lathes iyo nooca Swiss. Lathes-nooca Swiss-ku waa mid gaar ah oo alaabta kaydka ah lagu quudiyo hagaha hagaha, taas oo u oggolaanaysa qalabku inuu gooyo meel u dhow meesha taageerada, taas oo ka dhigaysa inay si gaar ah faa'iido u yeeshaan muddo dheer, qaybo caato ah oo CNC ah qaybaha lathe iyo micromachining. Qaar ka mid ah lathes nooca Swiss sidoo kale waxay la yimaadaan qalabaysan madax qalab labaad oo u shaqeeya sida aCNC Mill, iyaga oo u oggolaanaya in ay qabtaan hawlo badan oo mashiinno ah iyaga oo aan u guurin shaqada mashiinka kale. Tani waxay ka dhigaysa nooca Swiss-ka mid aad qaali u ah qaybaha rogan ee leh adeegyada laysarka CNC.

Noocyada CNC Lathes

SidaCNC, Lathes CNC si fudud ayaa loo dejin karaa dib u soo celinta sare, taas oo ka dhigaysa mid aad u fiican wax kasta oo ka soo baxa prototyping degdeg ah ilaa wax soo saarka hoose iyo sare. Xarumo rogid oo kala duwan oo CNC ah iyo lathe-nooca Swiss waxay u oggolaanayaan hawlo badan oo farsamayn oo hal mashiin ah. iyaga oo ka dhigaya ikhtiyaar wax ku ool ah oo loogu talagalay joomatariyada adag ee haddii kale u baahan doona mashiinno badan ama isbeddelka aaladaha warshadda CNC ee dhaqameed.

Noocyada CNC Lathes

●Haddii aad si dhakhso ah ugu baahan tahay qaybo tayo sare leh, oo caado u ah, adeegyadeena beddelka CNC waa doorasho aad u fiican. Dukaankayaga mashiinka CNC, waxaan isticmaalnaa qalab casri ah iyo hawl-wadeeno khibrad leh si aan u abuurno qaybo sax ah oo leh xawaare iyo saxsanaan gaar ah.

● Adeegyadayada degdega ah ee CNC waxay ku habboon yihiin wax-soo-saarka wax-soo-saarka hooseeya ama dhexdhexaadka ah. Waxaan ku takhasusnay abuurista qaybo gaar ah oo laga helo agabyo kala duwan, oo ay ku jiraan birta, balaastigga, iyo alwaax. Waxaan bixinaa noocyo kala duwan oo dhameystir ah, oo ay ku jiraan aluminium anodized iyo daahan PTFE.

● Habka rogidashadayada CNC waxay ku bilaabataa naqshad la sameeyay iyadoo la isticmaalayo software CAD. Naqshadeynta ayaa markaa loo rogaa kood kood uu akhrin karo oo la socon karo CNC. Hawlwadeenku waxa uu dejinayaa mishiinka isaga oo ku dhejinaya qalabka shaqada ee laashka oo ku rakibaya qalabka lagama maarmaanka ah.

● Marka mishiinku diyaar yahay, hawlwadeenku wuxuu bilaabayaa hawsha. Lathe CNC wuxuu ku wareegayaa qalabka shaqada xawaare sare halka qalabka goynta uu ku socdo walxaha, isaga oo ka saaraya walxaha xad-dhaafka ah ilaa qaybtu gaadho qaabka iyo cabbirka la doonayo.

● Adeegyadayada degdega ah ee CNC waxay bixiyaan faa'iidooyin badan. Marka hore, waxaanu si dhakhso ah u soo saari karnaa qaybo gaar ah, oo leh wakhti aad uga gaaban hababka wax soo saarka ee soo jireenka ah. Intaa waxaa dheer, saxnaantayada iyo saxnaantayadu waa mid aan isbarbardhigi karin, taas oo ay ugu wacan tahay qalabkayada casriga ah iyo hawl-wadeennada khibradda leh.

● Waxaan sidoo kale bixinaa adeeg macaamiil iyo taageero aad u wanaagsan inta lagu jiro habka oo dhan. Laga soo bilaabo naqshadeynta ilaa bixinta, waxaan si dhow ula shaqeynaa macaamiisheena si aan u hubinno inay helaan qaybaha tayada ugu sarreeya wakhtiga ugu yar ee suurtogalka ah.

Gebogebadii, adeegyadeena degdega ah ee CNC ee tayada sare leh ayaa ah doorasho aad u fiican baahiyahaaga wax soo saarka. Haddii aad u baahan tahay hal tusaale ama socodsiin wax soo saar oo ballaaran, waxaan ku gaarsiin karnaa qaybo gaar ah si degdeg ah oo sax ah.

Awoodaha ugu badan ee leexashada CNC

| Xaddidaadaha cabbirka qaybta | Unugyada mitirka | Unugyada Imperial |

| Dhexroorka qaybta ugu badan | 431 mm | 17 in |

| Dhererka qaybta ugu badan | 990 mm | 39 in |

| Lulida ugu badan ee gaariga | 350 mm | 13.7 inji |

| Daloollada ugu badan ee dunta | 40 mm | 1.5 inji |

Dahaarka budada

Halkan waxaa ah liiska agabka farsamaynta CNC ee la heli karo.

Biraha CNC

| Caagadaha | Caag la xoojiyay |

| ABS | Gaarolite G-10 |

| Polypropylene (PP) | Polypropylene (PP) 30% GF |

| Naylon 6 (PA6/PA66) | Naylon 30% GF |

| Delrin (POM-H) | FR-4 |

| Acetal (POM-C) | PMMA (acrylic) |

| PVC | DAAWO |

| HDPE | |

| UHMW PE | |

| Polycarbonate (PC) | |

| PET | |

| PTFE (Teflon) |

Dulqaadka

Waxaan raacnaa heerarka ISO 2768 ee Mashiinnada CNC.

| Xadka cabbirka magaca | Caagadaha (ISO 2768- m) | Biraha (ISO 2768-f) |

| 0.5mm* ilaa 3mm | ±0.1mm | ±0.05mm |

| In ka badan 3mm ilaa 6mm | ±0.1mm | ±0.05mm |

| In ka badan 6mm ilaa 30mm | ±0.2mm | ±0.1mm |

| In ka badan 30mm ilaa 120mm | ±0.3mm | ±0.15mm |

| In ka badan 120mm ilaa 400mm | ±0.5mm | ±0.2mm |

| In ka badan 400mm ilaa 1000mm | ±0.8mm | ±0.3mm |

| In ka badan 1000mm ilaa 2000mm | ±1.2mm | ±0.5mm |

| In ka badan 2000mm ilaa 4000mm | ±2mm |

- Fadlan si cad u muuji dulqaadka cabbirrada magaca ka hooseeya 0.5mm sawirka farsamadaada.

Tilmaamaha naqshadeynta ee CNC

Jadwalka hoose wuxuu soo koobayaa qiyamka lagu taliyey iyo farsamo ahaan macquulka ah ee sifooyinka ugu caansan ee lagu kulmo qaybaha mashiinka CNC.

| Muuqaal | Cabbirka lagu taliyay | Cabirka macquulka ah |

| Min. cabbirka muuqaalka | Ø 2.5 mm | Ø 0.5 mm |

| Cidhifyada gudaha | R 8 mm | R 0.25 mm |

| Dhumucda gidaarka ugu yar | 0.8 mm (biraha) | 0.5 mm (biraha) |

| 1.5 mm ( balaastik ah) | 1.0 mm ( balaastik ah) | |

| Godad | Dhexroor: cabbirrada laydhka caadiga ah | Dhexroorka: Ø 0.5 mm |

| Qoto dheer: 4 x dhexroor | Qoto dheer: 10 x dhexroor | |

| Xargaha | Cabirka: M6 ama ka weyn | Cabbirka: M2 |

| Dhererka: 3 x dhexroor |